As a rail enthusiast, I have always been captivated by the complex mechanics that allow trains to navigate safely along the tracks. Have you ever wondered how these massive machines manage to stay on course, especially during high speeds and sharp turns? In this guide, I will explore the fascinating mechanisms behind rail travel, from the design of the tracks to the engineering of the train itself. Understanding how trains stay on track is not only intriguing, but it also contributes to a greater appreciation for the safety and efficiency of this mode of transportation. So, let’s delve into the intricate details of rail travel and uncover the secrets of how trains stay on the track.

Key Takeaways:

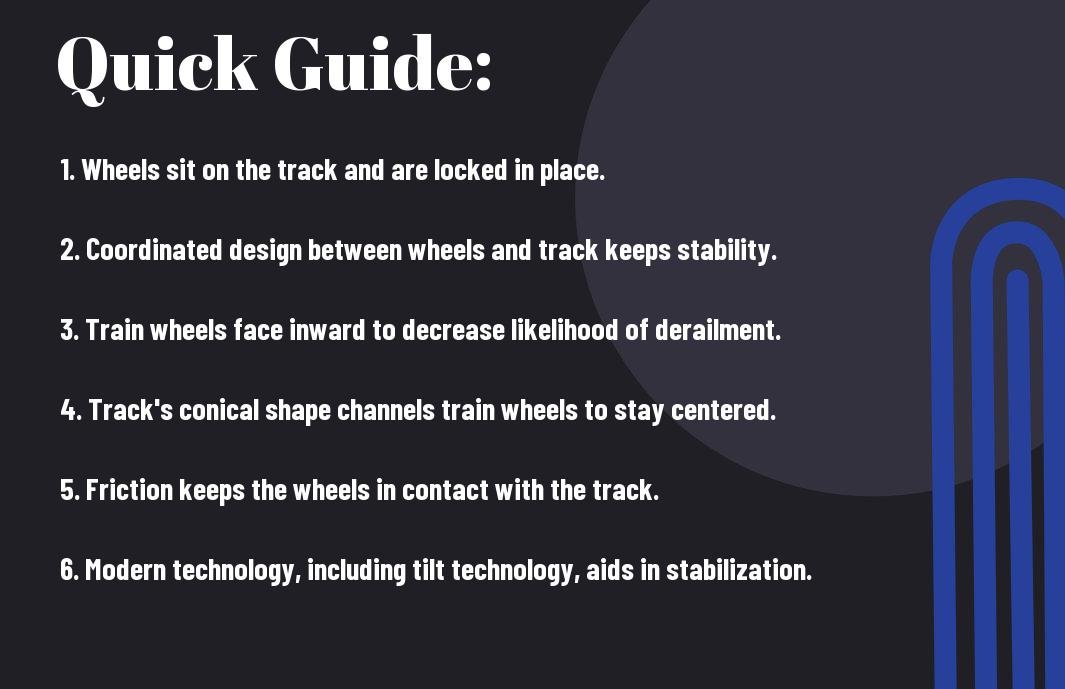

- Friction is essential: Trains stay on the track primarily due to the friction between the wheels and the track. This friction provides the necessary force to keep the train on its path.

- Wheel coning is crucial: The slight slope on the inside edge of train wheels, known as coning, helps the train stay centered on the track, especially when navigating curves.

- Powerful suspension systems: Trains are equipped with advanced suspension systems that help absorb shock and vibrations, ensuring a smooth and seamless ride while maintaining stability on the track.

- Track maintenance is key: Regular maintenance of the track, including proper alignment, leveling, and clearing of debris, is crucial to ensuring the stability and safety of train travel.

- Advanced technology plays a role: Modern trains utilize advanced technology, such as electronic monitoring systems and automatic control mechanisms, to further enhance their stability and safety on the track.

Types of Train Track Systems

To understand how trains stay on the track, it is important to look at the different types of track systems that are used in rail travel. There are various track systems that are used worldwide, each with its own unique characteristics and mechanics. Let’s explore the different types of track systems that trains operate on.

| Conventional Track Systems | Maglev Track Systems |

Conventional Track Systems

Conventional track systems are the most commonly used track systems for railway transportation. These track systems consist of steel rails, wooden or concrete crossties, and ballast. The train wheels run along the inside of the steel rails, and the weight of the train is distributed through the wheels onto the track. Conventional track systems are known for their durability and cost-effectiveness. However, they require regular maintenance to ensure smooth and safe operation. Perceiving the importance of maintaining these track systems is crucial for the safety of rail travel.

Maglev Track Systems

Maglev track systems, short for magnetic levitation track systems, are a newer and more advanced form of track technology. These track systems use magnetic levitation to propel the train forward, eliminating the need for traditional steel rails. Maglev trains float above the track through the use of powerful magnets, allowing for higher speeds and smoother rides. One of the greatest advantages of Maglev track systems is the reduced friction between the track and the train, resulting in quieter and more efficient travel. However, the cost of constructing maglev track systems can be significantly higher than conventional tracks, making them less common in many parts of the world.

Tips for Maximizing Train Track Stability

Obviously, ensuring proper track maintenance is crucial for maximising train track stability. This involves regular inspections, repairs and upgrades to the rail infrastructure to prevent any potential hazards.

- Regular track maintenance is essential to prevent wear and tear that can lead to derailments.

- Proper weight distribution on the train is critical for maintaining stability on the track.

- Speed management is also important as excessive speed can lead to instability and potential accidents.

Assume that proper track maintenance needs to be a top priority for ensuring the safety and stability of train travel.

Regular Track Maintenance

Regular track maintenance is essential for ensuring the safety and stability of train travel. This involves inspecting the track for any signs of wear and tear, as well as conducting necessary repairs and upgrades. By keeping the track in optimal condition, the risk of derailments and accidents can be significantly reduced, ensuring a smooth and secure journey for passengers and cargo.

Proper Weight Distribution

Proper weight distribution on the train is crucial for maintaining stability on the track. An uneven distribution of weight can lead to issues such as tipping or derailments, posing significant risks to both passengers and crew. By ensuring that the weight is distributed evenly and within safe limits, the stability of the train on the track can be maximised, reducing the likelihood of accidents and enhancing overall safety.

Step-by-Step Guide to Laying Train Tracks

For this chapter, I will guide you through the process of laying train tracks. This is a crucial aspect of rail travel and involves meticulous planning, precision, and attention to detail. Below, I have broken down the information into a table with two columns to provide a thorough understanding of the process.

| Step | Description |

| 1 | Preparing the Ground |

| 2 | Laying the Rails |

| 3 | Attaching the Sleepers |

| 4 | Ballasting the Tracks |

| 5 | Aligning and Leveling the Tracks |

Preparing the Ground

Before laying the tracks, the ground must be prepared to provide a stable foundation. This involves clearing the land of any obstructions, leveling the ground, and ensuring proper drainage to prevent water accumulation. Additionally, the ground must be compacted to prevent settling, which could lead to track misalignment. It is important to conduct a thorough inspection of the ground before commencing any work to prevent any potential issues down the line.

Laying the Rails

Once the ground is prepared, the rails can be laid out according to the planned track alignment. This requires precise measurements and careful placement to ensure the tracks are straight and properly aligned. Specialized equipment such as track jigs and gauges are used to ensure accuracy during this process. It is crucial to handle the rails with care and attention to detail to avoid any potential misalignments that could pose a safety risk.

Factors Affecting Train Track Stability

Keep in mind that several factors play a role in ensuring the stability of a train on its tracks. These can include weather conditions, train speed, and weight distribution among others. Understanding these factors is crucial not only for the safe operation of trains but also for the overall efficiency of rail travel.

Weather Conditions

Weather conditions greatly impact the stability of train tracks. Rain, snow, and extreme temperatures can pose a significant challenge to the integrity of the tracks. The expansion and contraction that occurs due to temperature changes can cause the tracks to shift, while moisture from rain or snow can affect the traction of the wheels. Additionally, strong winds can also push the train off track. As a result, railway companies invest heavily in maintenance and inspection protocols to mitigate the effects of adverse weather conditions on the track infrastructure.

Train Speed and Weight

The speed and weight of a train are crucial factors in maintaining track stability. As a train travels at high speeds, the force exerted on the tracks increases, potentially leading to track deformation and loss of stability. The weight of the train also plays a significant role, as uneven weight distribution or excessive loads can put a strain on the tracks. Regular inspections and maintenance of the track structure are paramount to ensuring that it can withstand the stresses imposed by varying speeds and heavy loads. Thou

Pros and Cons of Different Train Track Systems

Your choice of train track system can significantly impact the performance, efficiency, and safety of rail travel. Here, I will break down the pros and cons of conventional and maglev track systems to help you understand the benefits and drawbacks of each.

Conventional Track Systems

Conventional track systems, which include ballasted and non-ballasted tracks, are the most common type of railway system in the world. They consist of rails mounted on wooden or concrete sleepers, with ballast providing support and stability. Despite their widespread use, conventional track systems have their own set of advantages and disadvantages.

Maglev Track Systems

Maglev, short for magnetic levitation, involves trains that are suspended, guided, and propelled using powerful magnets instead of traditional steel wheels and rails. This innovative technology offers several advantages over conventional track systems, but it also comes with its own set of drawbacks.

I hope this gives insight into the pros and cons of different train track systems.

Conclusively

Understanding the mechanics of rail travel offers insight into the impressive technology that allows trains to stay on the tracks. From the design of the wheels and the tracks to the use of friction and centrifugal force, the combination of these elements ensures that trains can safely and efficiently transport passengers and cargo. By unraveling the complexities of rail travel, we gain a greater appreciation for the engineering marvels that make modern transportation possible. The next time you board a train, you can be confident that the intricate mechanics at play are keeping you on track.

FAQ

Q: How do trains stay on the track?

A: Trains stay on the track through a combination of factors, including the design of the wheels and tracks, as well as the force of friction. The flanged wheels of the train fit securely on the inside of the track, preventing the train from derailing. Additionally, the weight of the train and the force of friction between the wheels and the track help to keep the train on its intended path.

Q: What prevents trains from derailing?

A: Various safety mechanisms are in place to prevent trains from derailing. This includes the use of track inspections, maintenance, and the implementation of signaling systems and speed limits. Additionally, modern trains are equipped with advanced suspension and stabilization systems to ensure stability and prevent derailment.

Q: How are train tracks constructed to support the weight of trains?

A: Train tracks are constructed with durable materials, such as steel or concrete, to support the weight and force exerted by trains. The tracks are laid on a bed of rocks or concrete to provide stability and to distribute the weight of the train evenly. The tracks are also designed with a slight incline on curves to counteract the centrifugal force and keep the train on the track.

Q: What role does friction play in keeping trains on the track?

A: Friction is a crucial element in keeping trains on the track. The friction between the wheels and the track provides the necessary resistance for the train to move forward and stay on its designated path. The wheels are designed to have a specific profile to optimize the friction and ensure that the train can navigate curves and maintain its stability.

Q: Are there safety measures in place to prevent train accidents?

A: Yes, there are extensive safety measures in place to prevent train accidents. These include regular track inspections, maintenance of the train components, implementation of signaling and communication systems, and adherence to speed limits. Additionally, advanced technologies such as automatic braking systems and train control systems are utilized to enhance safety and prevent accidents.